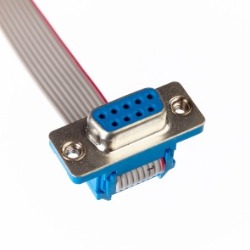

A molded cable is a type of electrical cable characterized by its protective outer casing, which is formed through a molding process. This molding process involves the application of heat and pressure to encase the cable’s conductive wires within a durable, often plastic, sheath. Molded cables are widely used in various applications due to their enhanced durability, flexibility, and protection against environmental factors.

The core of the cable contains one or more conductors, which are usually made of copper or aluminum. These conductors are responsible for transmitting electrical signals or power. Surrounding the conductors is an insulating layer that prevents electrical shorts and ensures safe operation.

The molding process involves placing the insulated conductors into a mold and then injecting or compressing a molten plastic material around them. This plastic material solidifies to form a strong, cohesive outer sheath. Common materials used for the molded sheath include PVC (Polyvinyl Chloride), TPE (Thermoplastic Elastomer), and rubber compounds. These materials are chosen for their insulating properties, flexibility, and resistance to abrasion, chemicals, and weather conditions.

Advantages:

Durability: The molded sheath provides excellent protection against mechanical damage, such as abrasion, cuts, and impacts. This makes molded cables ideal for use in environments where the cable may be subject to physical stress or harsh conditions.

Flexibility: Molded cables are designed to remain flexible even in extreme temperatures. This flexibility allows for easy installation and routing in various applications, including those that involve tight spaces or frequent movement.

Environmental Resistance: The outer molded sheath protects the internal conductors from environmental factors such as moisture, UV radiation, and chemicals. This ensures reliable performance in outdoor or industrial environments.

Aesthetics and Organization: Molded cables often have a streamlined, uniform appearance, which can be aesthetically pleasing and contribute to a neater and more organized setup. This is particularly beneficial in applications like electronics and consumer devices.

Enhanced Safety: The molded construction provides a solid barrier against electrical shorts and reduces the risk of exposed wires, enhancing overall safety for both users and equipment.

Applications:Molded cables are used in a variety of applications across different industries. In consumer electronics, they are commonly found in power cords, audio/video cables, and USB cables. In industrial settings, molded cables are used for machinery connections, control systems, and data transmission. They are also employed in automotive applications for wiring harnesses and connections.

Considerations:When selecting a molded cable, it is important to consider factors such as the cable's voltage and current rating, flexibility requirements, and environmental conditions. The choice of material for the molded sheath can affect the cable's performance and durability.