LVDS (Low-Voltage Differential Signaling) cable assemblies are specialized components designed to transmit high-speed data over relatively short distances with minimal electromagnetic interference and signal degradation. These assemblies are crucial in computer monitors, televisions, and other digital devices systems, especially where high data rates and high-resolution displays are required.

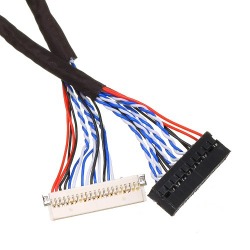

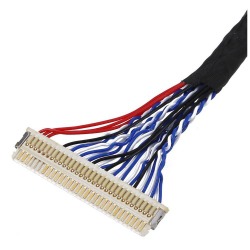

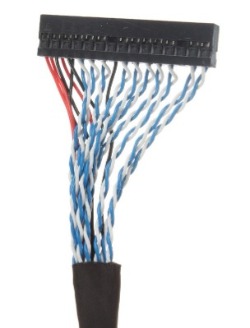

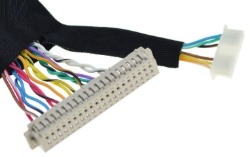

The cable used in LVDS assemblies is typically a twisted pair configuration, where pairs of conductors are twisted together to reduce electromagnetic interference (EMI) and crosstalk between signals. The conductors themselves are usually made from high-purity copper to provide minimal resistance and high conductivity.

To further mitigate EMI and signal degradation, LVDS cables often include shielding. This can be in the form of foil shields, braided shields, or a combination of both. Shielding helps to protect the delicate differential signals from external noise and interference, ensuring stable and reliable data transmission.

The connectors are typically designed to handle high data rates and maintain the integrity of the differential signals. Common connector types for LVDS assemblies include high-density headers, ribbon connectors, and custom connectors specific to the application.

High-quality insulation materials help prevent short circuits and signal leakage.

Key applications of LVDS cable assemblies include:Display Interfaces: LVDS is commonly used in connecting displays to their controllers in laptops, monitors, and televisions.

Data Communications: LVDS cable assemblies are also used in data communication systems where high-speed data transfer is necessary. This includes applications such as network equipment, digital signal processors, and high-performance computing systems.

Automotive Electronics: In modern vehicles, LVDS technology is employed to handle data from various sensors, cameras, and infotainment systems. The robustness of LVDS against interference makes it suitable for the demanding environment of automotive applications.

Industrial Control Systems: LVDS assemblies are used in industrial settings for connecting control systems and monitoring equipment. The technology's reliability and noise immunity are beneficial in environments with significant electromagnetic interference.

AdvantagesHigh Data Rates:

LVDS technology can handle high-speed data transmission, supporting data rates from several hundred megabits per second to several gigabits per second.

Low Power Consumption: LVDS operates at lower voltages and currents compared to traditional single-ended signaling methods, reducing power consumption and heat generation.

Immunity to Interference: The differential nature of LVDS signals helps to minimize the effects of EMI and crosstalk, ensuring more stable data transmission.

Conclusion

LVDS cable assemblies play a crucial role in modern electronic systems by providing reliable, high-speed data transmission while minimizing power consumption and electromagnetic interference. Their design, including twisted pairs, shielding, and high-quality connectors, ensures that they meet the demands of various applications, from consumer electronics to industrial and automotive systems.